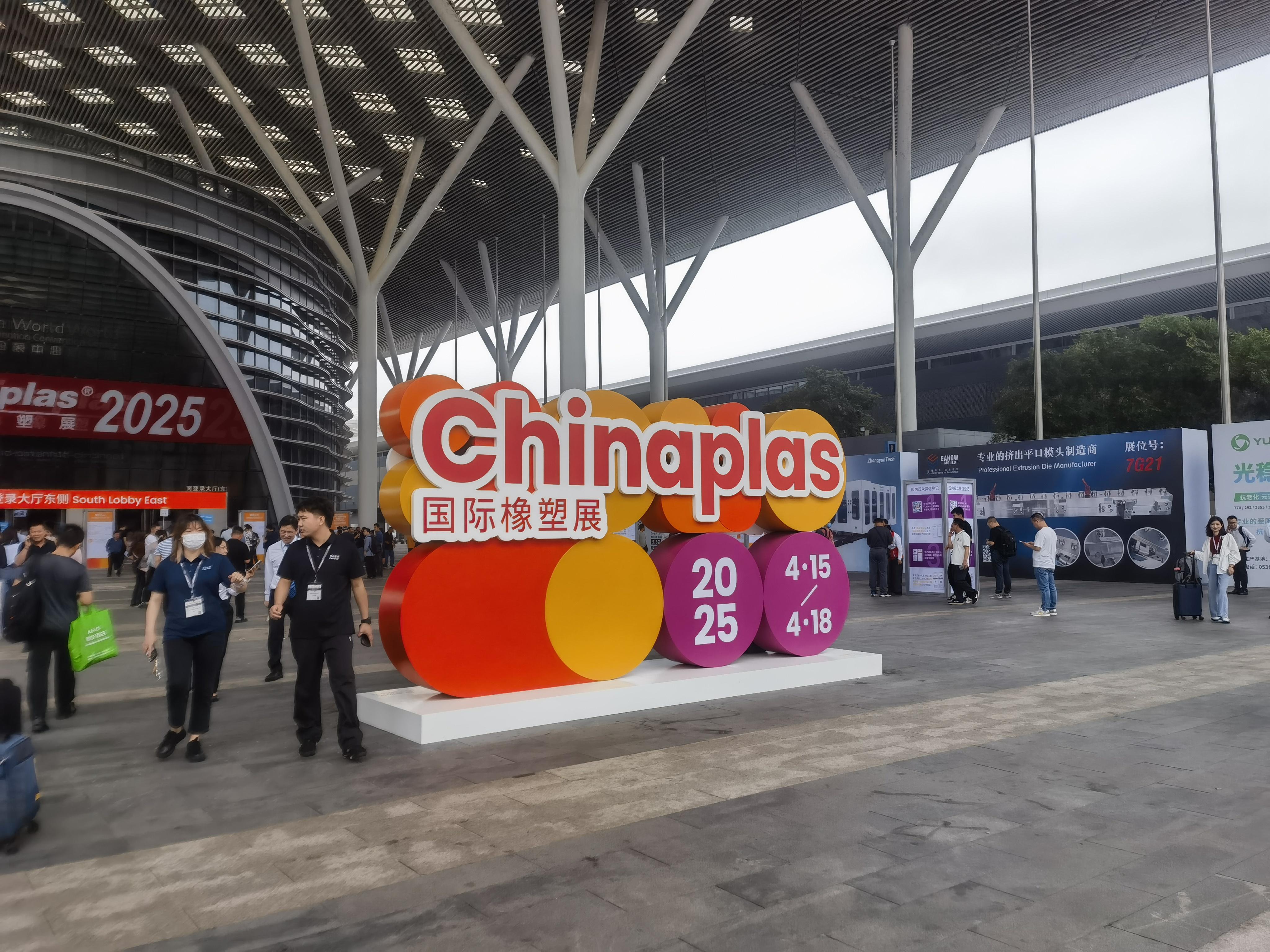

Anti-blocking agents at CHINAPLAS 2025

Vinyl resin in CHINAPLAS 2025

Date: 2025-04-29 09:06

Category: News

Author: Admin

At CHINAPLAS 2025 in Shenzhen, major global players like Shin-Etsu and Formosa Plastics, alongside numerous domestic Chinese companies, showcased a wide range of vinyl resins, primarily PVC and its copolymers, for diverse applications in construction, packaging, and automotive. Sustainability and specialized performance grades were key highlights.

Reflecting on CHINAPLAS 2025 held in Shenzhen from April 15th to 18th, the Vinyl Resin section showcased a variety of vinyl polymers, primarily PVC (Polyvinyl Chloride) and its copolymers, as well as PVAC (Polyvinyl Acetate) and PVB (Polyvinyl Butyral), crucial for a wide range of applications in construction, packaging, automotive, and consumer goods. Both international and domestic manufacturers presented their latest innovations, focusing on performance, sustainability, and specialized formulations.

Likely Exhibitors and Their Offerings:

Shin-Etsu Chemical Co., Ltd. (Japan/Global): A major global producer of PVC and specialty vinyl resins, Shin-Etsu likely showcased its extensive range of PVC grades for various processing methods (extrusion, calendering, injection molding) and applications (pipes, profiles, films, compounds). They might have also highlighted their specialty vinyl chloride copolymers and PVB resins for automotive glazing and coatings.

Formosa Plastics Group (Taiwan/Global): As one of the world's largest PVC producers, Formosa Plastics likely presented its broad portfolio of PVC resins, compounds, and downstream products. Their focus might have been on high-volume PVC applications in construction and infrastructure.

Westlake Chemical Corporation (USA/Global): Westlake, a significant integrated producer of PVC, likely showcased its range of PVC resins and compounds for diverse applications, including pipes, siding, and flexible PVC products.

Vinnolit GmbH & Co. KG (Germany/Global, part of Orbia): Vinnolit, a leading European PVC producer, likely presented its specialty PVC grades, including paste grades for flooring and coatings, as well as high-performance suspension and emulsion PVC.

INEOS Inovyn (UK/Global): INEOS Inovyn, a major PVC producer in Europe, likely showcased its range of PVC resins and compounds for various applications, emphasizing sustainability initiatives and product innovation.

Domestic Chinese Companies: China is a major producer of PVC and other vinyl resins, and numerous domestic companies would have exhibited at CHINAPLAS 2025. Key categories and potential (though not exhaustive) company types include:

Large-scale PVC producers: Companies like Tianjin Bohai Chemical Industry Group Corp. (天津渤海化工集团公司), Shandong Dongyue Group Co., Ltd. (山东东岳集团有限公司), and numerous others would have presented their general-purpose and specialty PVC grades.

PVC compounders: Companies specializing in formulating PVC compounds with various additives for specific applications (e.g., rigid PVC for profiles, flexible PVC for cables). Look for companies advertising "PVC 树脂" (PVC resin) and "PVC 塑料" (PVC plastics).

PVAC and PVB producers: While PVC dominates, some domestic companies also produce polyvinyl acetate (used in adhesives and coatings) and polyvinyl butyral (used in automotive glazing and inks). Specific company names can vary.

Trading Companies: Numerous trading companies representing both international and domestic vinyl resin manufacturers would have been present.

Focus Areas at the Exhibition:

Exhibits likely highlighted:

Sustainability: Efforts towards PVC recycling, bio-based additives for PVC, and the development of more sustainable vinyl alternatives.

Performance Enhancements: PVC grades with improved impact resistance, weatherability, and thermal stability.

Specialized Applications: Vinyl resins tailored for specific industries like automotive (interior parts), medical (flexible PVC), and packaging (films).

Processing Technologies: Resins designed for efficient processing through extrusion, calendering, and injection molding.

Cost-Effectiveness: Solutions catering to the price-sensitive Chinese market while maintaining quality standards.

In summary, CHINAPLAS 2025 likely featured a significant presence of vinyl resin manufacturers, both global leaders and numerous domestic producers, showcasing a wide range of PVC, PVAC, and PVB grades and compounds for diverse applications, with an increasing emphasis on sustainability and specialized performance.

fumed silica

white carbon black

pyrogenic silica

silicon dioxide

hydrophobic fumed silica

hydrophilic fumed silica

Synthetic Amorphous Silica

nanoscale fumed silica

high surface area fumed silica

silica nanoparticles

Shandong Yingrui New Materials Co., Ltd

Email: rhea@sdyingrui.cn; michael@sdyingrui.cn

Tel: +86 13285355246; +86 15154536501

Whatsapp: +8613583505605; +8615154536501

-----------------------------------------------------------------------------------------------------------------

回顾 2025 年 4 月 15 日至 18 日在深圳举行的 CHINAPLAS 中国国际橡塑展,乙烯基树脂展区展示了各种乙烯基聚合物,主要是 PVC(聚氯乙烯)及其共聚物,以及 PVAC(聚醋酸乙烯酯)和 PVB(聚乙烯醇缩丁醛),这些聚合物对于建筑、包装、汽车和消费品等广泛应用至关重要。众多国际和国内制造商展示了他们的最新创新成果,重点在于性能、可持续性和专业配方。

主要参展商及其产品回顾:

信越化学工业株式会社(日本/全球): 作为全球主要的 PVC 和特种乙烯基树脂生产商,信越很可能展示了其广泛的 PVC 等级,适用于各种加工方法(挤出、压延、注塑)和应用(管道、型材、薄膜、混合料)。他们可能还重点介绍了其特种氯乙烯共聚物和用于汽车玻璃和涂料的 PVB 树脂。

台湾塑胶工业股份有限公司(台湾/全球): 作为全球最大的 PVC 生产商之一,台湾塑胶很可能展示了其广泛的 PVC 树脂、混合料和下游产品组合。他们的重点可能在于建筑和基础设施中的大批量 PVC 应用。

威士雷科化学公司(美国/全球): 威士雷科是一家重要的 PVC 综合生产商,很可能展示了其用于各种应用(包括管道、壁板和柔性 PVC 产品)的 PVC 树脂和混合料系列。

Vinnolit GmbH & Co. KG(德国/全球,Orbia 旗下): Vinnolit 是欧洲领先的 PVC 生产商,很可能展示了其特种 PVC 等级,包括用于地板和涂料的糊状树脂,以及高性能悬浮和乳液 PVC。

英力士 Inovyn(英国/全球): 作为欧洲主要的 PVC 生产商,英力士 Inovyn 很可能展示了其用于各种应用的 PVC 树脂和混合料系列,并强调了可持续发展倡议和产品创新。

中国国内企业: 中国是主要的 PVC 和其他乙烯基树脂生产国,众多国内公司参加了 CHINAPLAS 2025。主要类别和潜在(但非详尽)的公司类型包括:

大型 PVC 生产商: 天津渤海化工集团公司、山东东岳集团有限公司等众多企业很可能展示了其通用和特种 PVC 等级。

PVC 混料商: 专门为特定应用(例如用于型材的硬质 PVC,用于电缆的柔性 PVC)配制含各种添加剂的 PVC 混合料的公司。寻找宣传“PVC 树脂”和“PVC 塑料”的公司。

PVAC 和 PVB 生产商: 虽然 PVC 占主导地位,但一些国内公司也生产聚醋酸乙烯酯(用于粘合剂和涂料)和聚乙烯醇缩丁醛(用于汽车玻璃和油墨)。具体公司名称可能有所不同。

贸易公司: 众多代表国际和国内乙烯基树脂制造商的贸易公司也 присутствовали.

展会上的重点领域回顾:

展品很可能突出了:

可持续性: 在 PVC 回收、PVC 生物基添加剂以及更可持续的乙烯基替代品的开发方面的努力。

性能提升: 具有改进的抗冲击性、耐候性和热稳定性的 PVC 等级。

专业应用: 专为汽车(内饰件)、医疗(柔性 PVC)和包装(薄膜)等特定行业量身定制的乙烯基树脂。

加工技术: 专为通过挤出、压延和注塑实现高效加工而设计的树脂。

成本效益: 在保持质量标准的同时满足价格敏感的中国市场的解决方案。

总而言之,CHINAPLAS 2025 很可能汇集了众多乙烯基树脂制造商,包括全球领导者和众多国内生产商,展示了广泛的 PVC、PVAC 和 PVB 等级和混合料,适用于各种应用,并越来越强调可持续性和专业性能。